What is MIM?

The full name of MIM is metal injection Molding. It is a molding method, which injects the medal powder and plasticizing mixture of binder into the model.

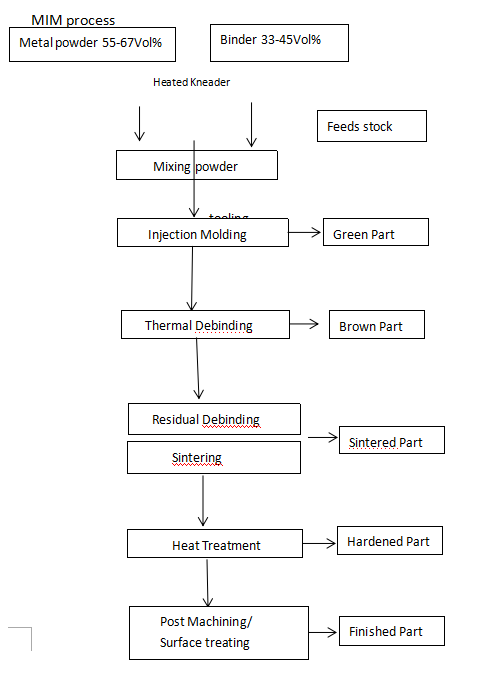

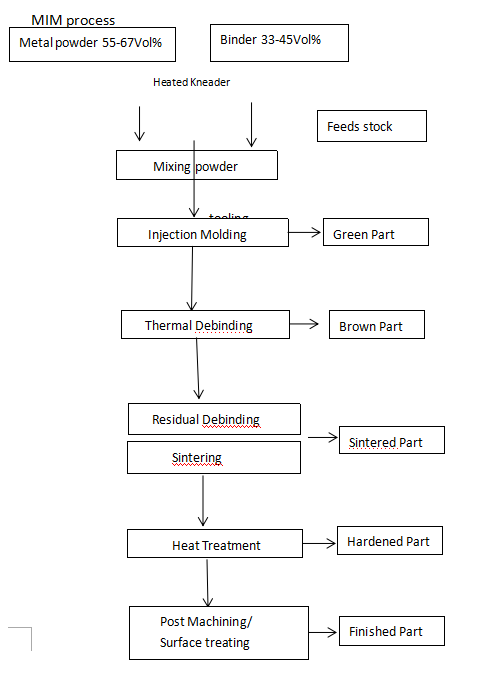

Firstly, it mixes selective powder with binder. Then, granulate the mixture and inject into the model which is needed. The mixture get the feature of polymer, which are viscidity and flow. It is helpful to modeling, mould filling and the homogeneity of powder packing. After it have taken shape, exclude the binder. Then, sinter the defatted germ. Some of the sintering products might have densifying treatment, heat treatment and machining treatment. Sintering products not only have the complex shape and high precision as the products made by plastic injection modeling method, but also have the physical, chemical and mechanical property as forge piece.

This technical skill is suitable for volume-produce to make small size,precise,complicated 3D-shaped metal parts which also require special performance.

Some details as below:

Step 1: Feedstock

· Very fine metal powders usually (<15 microns) are mixed with a primary paraffin material and a secondary thermoplastic polymer. Together they act as binders

· Unlike standard powder metalurgy, which can achieve only 80-90% of theoretical density, MIM results in 95-100%. This means we can achieve close tolerances and reduce costs by producing small, complex parts over high production runs

Step 2: Molding

· The feedstock is fed into either our multi-slide MIM machinery or standard molding equipment, then heated and injected into a mold cavity under high pressure

· Our proprietary multi-slide tooling can produce extremely complex shapes and allow for shorter cycle times

· Once molded, the component is referred to as a “green” part

· Our multi-slide process routinely produces green parts in 3 seconds as opposed to 25-40 seconds on a standard MIM system

· Its geometry is identical to that of the finished piece, but to allow for shrinkage during the sintering phase, it’s about 20% larger in size than the finished component will be

Step 3: Debinding

· Binder removal or “debinding” involves a controlled process to remove most of the binders

· The process removes the binders and prepares the part for the final step – sinterin

· Once debinding is complete, the component is referred to as “brown”

Step 4: Sintering

· The “brown” part is held together by a small amount of the binder, and is very fragile

· Sintering eliminates the remaining binder and gives the part its final geometry

· During sintering, the part is subjected to temperatures near the melting point of the material

· The entire sintering process takes 15-20 hours

You could see below information if using a chart to get a conclusion