MIM process flow MIM process scheme

Step 1: Feedstock

· Very fine metal powders usually (<15 microns) are mixed with a primary paraffin material and a secondary thermoplastic polymer. Together they act as binders

· Unlike standard powder metalurgy, which can achieve only 80-90% of theoretical density, MIM results in 95-100%. This means we can achieve close tolerances and reduce costs by producing small, complex parts over high production runs

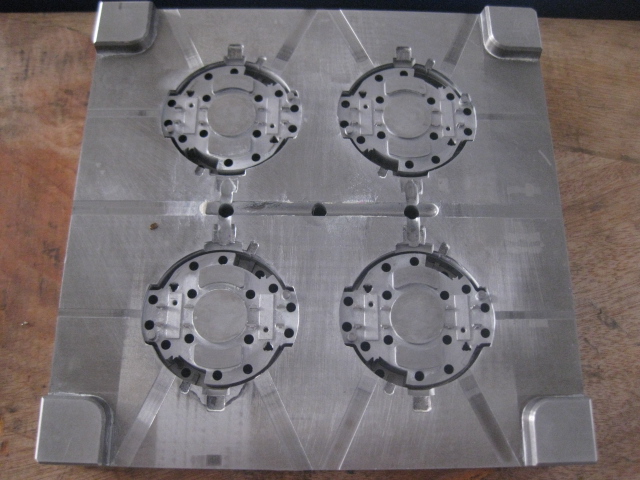

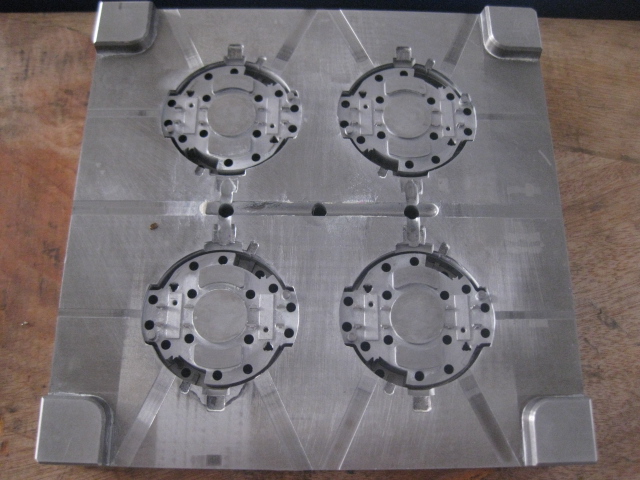

Step 2: Molding

· The feedstock is fed into either our multi-slide MIM machinery or standard molding equipment, then heated and injected into a mold cavity under high pressure

· Our proprietary multi-slide tooling can produce extremely complex shapes and allow for shorter cycle times

· Once molded, the component is referred to as a “green” part

· Our multi-slide process routinely produces green parts in 3 seconds as opposed to 25-40 seconds on a standard MIM system

· Its geometry is identical to that of the finished piece, but to allow for shrinkage during the sintering phase, it’s about 20% larger in size than the finished component will be

Step 3: Debinding

· Binder removal or “debinding” involves a controlled process to remove most of the binders

· The process removes the binders and prepares the part for the final step – sinterin

· Once debinding is complete, the component is referred to as “brown”

Step 4: Sintering

· The “brown” part is held together by a small amount of the binder, and is very fragile

· Sintering eliminates the remaining binder and gives the part its final geometry

· During sintering, the part is subjected to temperatures near the melting point of the material

· The entire sintering process takes 15-20 hours

Step 5: Post Machining

·This process could be made as drawings requirements like CNC, drilling, threading,surface treatment etc.